What Are The Types Of Plastics? A Quick Guide To Synthetic Polymers.

The Basics of Synthetic Polymers

Synthetic Polymers Properties:

- Easy to Mold

- Low Thermal Conductivity

- Longevity

- Versatility

- Durability

- Lightweight

- Tensile Strength

- Electrical and Thermal Insulation

- Corrosion and Chemical Resistance

- Transparency

- Flexibility

- Water Resistance

- Cost-Effective

- Recyclability

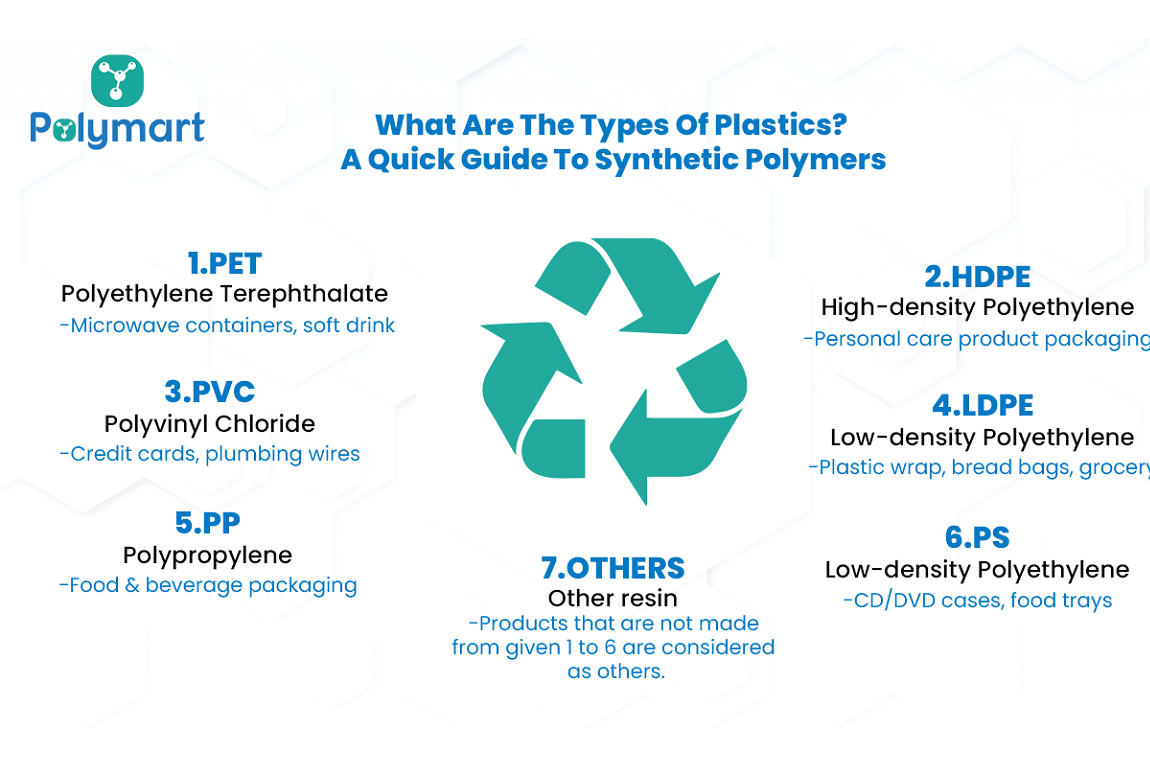

5+ Types of Plastic/Polymers You'll Find Nearly Everywhere

Rc- no

Plastic Type

Resin Identification Code

Applications

Polyethylene Terephthalate (PET) - #1

High-density Polyethylene (HDPE) - #2

Polyvinyl Chloride (PVC) - #3

Low-density Polyethylene (LDPE) - #4

Polypropylene (PP) - #5

Polypropylene, one of the most commonly used synthetic polymers in our daily lives, is known for its high chemical resistance and excellent thermal stability. It is well-suited for packaging purposes and the production of plastic films.

Polystyrene (PS) - #6

The monomer styrene is utilized in the production of polystyrene, a synthetic hydrocarbon polymer. Plastic forks, DVD cases, stationery, toys, and various packaging materials are primarily manufactured from this rigid, transparent,

and brittle material. Polystyrene exhibits a styrofoam-like texture and excellent thermal insulation properties.

Other Plastic Resins (O) - #7

Plastics that do not fall into the categories numbered 1 through 6 are classified as ‘other plastic resins,’ designated by code number 7. This category includes polycarbonate, polylactide, acrylic, acrylonitrile butadiene, styrene, fiberglass, and nylon. Examples of products made from these other plastics include plastic baby bottles, large water bottles, medical storage containers, eyeglasses, and exterior lighting fixtures.

In addition, these resins have been controversial in recent years: the reason for this is their degradation at high temperatures, which releases bisphenol A, a compound that is regarded as potentially hazardous to the environment. Plus, A 7 number type of plastic resin cannot be recycled.